Select your Vehicle..

View all-

2021-2024 Isuzu D-MAX

All STORMOD storage modules - Modular Overlanding Storage Solutions - For Isuzu...

-

2021-2024 Mazda BT50

All STORMOD storage modules - Modular Overlanding Storage Solutions - For Mazda...

-

STORMOD Spare Parts

STORMOD storage modules spare parts - Modular Overlanding Storage Solutions

Featured STORMOD Modules

-

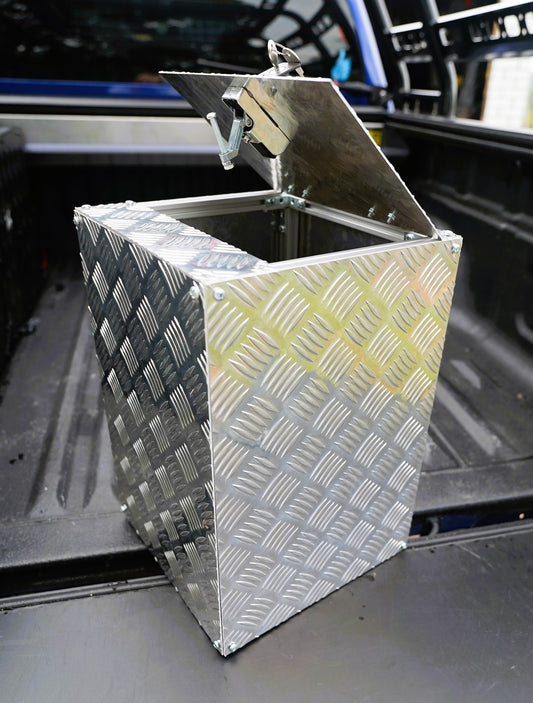

Isuzu D-MAX Mazda BT50 2021-24 - Square Storage Bin Module

Regular price $199.00 AUDRegular priceUnit price / per -

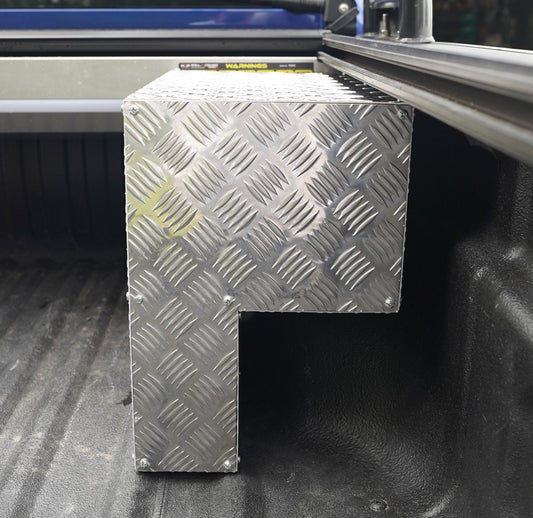

Isuzu D-MAX Mazda BT50 2021-24 - Over-Arch Box Module

Regular price $199.00 AUDRegular priceUnit price / per -

Isuzu D-MAX Mazda BT50 2021-24 - Triple Pack Storage Modules

Regular price $575.00 AUDRegular priceUnit price / per -

Isuzu D-MAX Mazda BT50 2021-24 - Big Boi Storage Bin

Regular price $199.00 AUDRegular priceUnit price / per -

STORMOD Spare Part - 21-24 D-MAX BT50 Over Arch - 500mm Length

Regular price $10.00 AUDRegular priceUnit price / per

The STORMOD Story

2 Years in the Making: Introducing STORMOD

In a previous 4wding life I built a Jeep JK with all the fruit and one of the most rewarding mods was the DIY storage solution in the back, squaring off the weird shapes into storage bins and compartments. This transformed my camping and overlanding experience - everything had a home, and I stopped forgetting to bring 'that thing' because it was always in the Jeep!

Fast forward a few years and I moved into a new series Isuzu D-MAX and my first proper dual cab ute. One of the first things I missed was the storage - I now had all this space in the tub but somehow nowhere to put things! I set to work...

After 2 years of literal CAD prototyping (cardboard aided

design) before moving to wooden tests, to actual prototypes with extrusion and checkerplate, the first designs of STORMOD were born. This 'final' prototype setup was 2x Square Storage Bin boxes and 1x Over-Arch Box. I ran this setup for over 12 months and tested the heck out it, many trips with gear thrashing around inside, full lithium 12v setups, even a fully loaded 8000 km Cape York trip.

Everything survived (I even still have the original), so I knew it was time to get into some serious development.

Rigorous testing was a crucial part of the STORMOD development process. We subjected prototypes to a series of tests to ensure durability, stability, and water resistance. These tests included weight capacity tests, vibration tests, and exposure to extreme weather conditions. The result is what we believe to be the strongest, most modular and customisable 4wd and Overlanding Storage Solution on the market.

After some 3 runs of initial production sold out, it was time to get serious and STORMOD was registered as it's own business and scaling began. A massive thank-you for your interest in the product and 'simplified DIY' concept, we look forward to seeing how you use our product and can't wait to show you what we're cooking up next!

Early prototyping

Initial idea testing and sizing - first was with 'CAD' (cardboard aided design) and this migrated to wood frames and putting in and out of the D-MAX tub 3453 times

Aluminium test

First prototype using actual aluminium extrusion similar

to what's used today. Note the supremely strong white corflute! Maybe not, but handy for quick mud maps on gear placement!

12v Testing

Early test of how much 12v gear can be squeezed into the original 'Over-Arch' design. This had 100AH Lithium, 2x MPPT, Air Compressor, 1000w inverter, Shunt and switch panel control

Final Prototype

This was the 'final' prototype of the initial set - 2x Square Storage Bins and 1x Over-Arch Box. You can see detail of this being put together in the VideoShowMeHow YouTube video series. We tested this exact setup for over a year.

Continuous Improvement

A tolerance example from an early production box. Quality

has been key from the start, and we still strive to improve quality and reduce costs for our customers every. single. day.